Storing Late Season Corn and Beans

By Sam McNeill, Biosystems and Agricultural Engineering

Allowable Storage Times

Table 1. Approximate allowable storage times (days) for corn and soybean in good condition at different temperature (T) and moisture levels based on a ½% dry matter loss, which represents a grade loss. Reduce table values by ½ for poor quality grain.

Notes:

1. An asterisk (*) indicates that the allowable storage time (AST) exceeds 300 days.

2. Keep in mind that the allowable storage time is cumulative. If 17% soybeans are held for 10 days at 50 F, one fifth (20%) of the storage life has expired, so when they are cooled to 40 degrees the approximate storage time is reduced to only 72 days (90 x 0.8).

3. The chart also shows the importance of cooling stored grain as quickly as possible during the Fall and keeping it cold throughout the storage period. Aeration fans should be sealed after the last aeration cycle to block wind-driven air currents from re-warming grain.

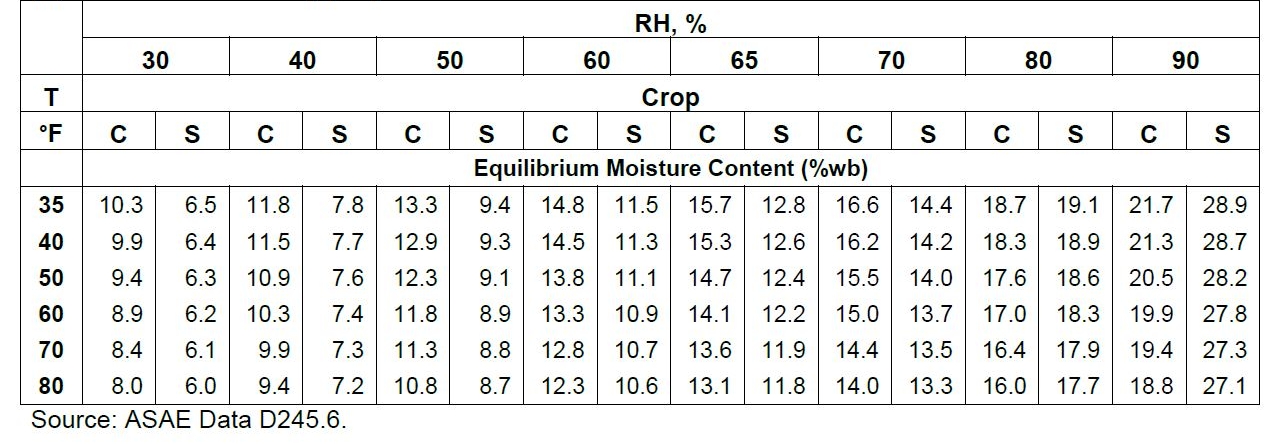

Equilibrium Moisture Content for Corn and Soybean:

Table 2. Equilibrium moisture content of yellow corn and soybean (%wb) at different temperature (T) and relative humidity (RH) levels.

Implications for drying:

Grain will eventually reach the moisture levels shown in Table 2 when exposed to the corresponding temperature and humidity levels for several days. This can occur in the field or in the top layers of a bin dryer.

Drying time will depend on the outside air conditions (temperature and humidity), initial and final grain moisture and airflow rate through grain, which in turn depends on the depth of grain in a bin. The minimum recommended drying rate for natural air drying when temperatures fall around 50 F is 2 cfm/bu, but this can take up to 15 days to dry the top layer of soybeans from 17% to 13% when the outside air is 50 F and 65% RH. In contrast, if the airflow is only 1 cfm/bu it will take twice as long to dry, during which time less than half the approximate storage time remains (Table 1). Moreover, a small amount of heat (~5 oF) is needed when the RH is above 70%, but too much heat (>10 oF above ambient) can lower the RH below 60% will over dry the bottom layer. The goal for bin dryers is to maintain temperature and RH conditions to match the desired target moisture.

Implications for corn storage:

The air (void) space between grain kernels in a bin will have the humidity indicated at the corresponding moisture and temperature. For example, 15% corn and 13.7% soybeans at 60 degrees will have a relative humidity in the void space of 70%, but when cooled to 35 degrees, corn will have a relative humidity of 62% and soybeans will have a relative humidity of 68%.

Mold growth is suppressed during storage when the environment is maintained at a relative humidity level of 65% or lower. Thus, beans should be dried below 13% and held at 35 oF during the winter months in Kentucky. If held into the spring or summer, soybeans will store better at 12% or 11.5%, respectively. Corresponding values for corn are 15% and 13%.

When bin space is limited, move corn to a grain bag or temporary storage structure with aeration (equipment shed or covered outdoor pile) to make room for soybeans and monitor both crops.

More information on grain drying and storage is available at county extension offices throughout Kentucky and on the UK-BAE web page: www.uky.edu/bae/grain-storage-systems